What is the standard of machine carpet? What are the dimensions of a standard rug?

2022-02-10 13:40:35

What is the standard of machine carpet? What are the standard dimensions of machine carpet?

The standard of machine-made carpets is a necessary and required thing in the Iranian standard law. Machine-made carpets, as a product of production and necessarily consumption, are required to comply with standard rules.

If some goods, such as foodstuffs or construction equipment, do not meet the standard, there is a threat to human life; But the carpet is not like this and not observing the standard conditions is not a special risk for the consumer.

One of the reasons defined for the machine-made carpet standard was to distinguish non-quality machine-made carpets from quality carpets.

Today, one third of the carpets produced are exported to foreign countries. The global market is a market for competing with qualities. If the manufacturer does not comply with the standards, it will suffer nothing but failure in the foreign market.

Since the seal of the Iranian Standards Organization is acceptable to many countries, carpet exporters are required to comply with the standards of this organization.

In domestic markets, observing the standard can relieve the consumer that the carpet has optimal conditions in terms of production and can assure the manufacturer in terms of quality.

Machine carpet standard, machine carpet quality

One of the things that needs to be mentioned before the standard items of machine-made carpets is the standard technical category.

Standard topics are not items that can be informed by eye or with the tools that are at home about its accuracy and accuracy, but require technical tools and equipment.

In carpet factories, there are laboratory units that check the quality items and send the samples to the standard office, and that organization will issue the relevant stamp for the company after reviewing and complying with the standard items. Therefore, in this article, we will deal with the most important conditions mentioned in the machine carpet standard.

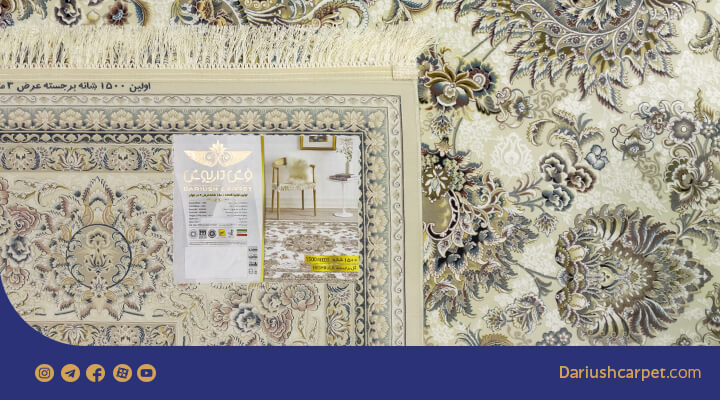

Since there are multiple standards in machine-made carpets, in this article we will talk about one of them, which is the standard of machine-made carpet labels.

Machine carpet standard on carpet label

One of the standard items of machine-made carpets is the standard label on the back of the carpet. This standard number 1360 is related to the information that should be exposed to the buyer of the carpet.

This information includes technical information that affects the quality of the carpet, if you are buying a car carpet, you should know how to check and control the information.

Standard machine carpet fibers

Sleeping thread: The first item that is printed on the label is sleeping thread. Sleeping yarn is actually the fibers that cover the background or surface of the carpet. According to the standard office, the sleeping thread is made of acrylic, polyester and polypropylene fibers.

Sleep yarn height: In the carpet standard, it does not talk about the amount of sleep yarn height, but defines the tolerance limit, which is determined by the tolerance limit in laboratories; But specifically, the height of the sleeping thread is between 3 and 25 mm so that we can refer to the carpet as a woven floor. Basically, the carpet is divided into two groups according to the sleeping thread

Homogeneous carpet: A carpet is said to have the same yarn in terms of material, density and height at the surface of the carpet.

Heterogeneous carpet: A carpet in which the sleeping thread is not the same in terms of shape, material, density and height on the surface of the carpet and even in some areas of the carpet there is no sleeping thread.

The higher the number of combs in a rug, the lower the height of the sleeping thread. As a result, the carpet looks better.

Quality of carpets and sleeping threads

After production, the carpet is divided into five quality grades. In the standard carpet machine, it is mentioned that if it is referred to as a first-class carpet, that

It is free of any defects.

The material of sleeping yarn in such carpets is acrylic heatset.

It is important to note that the fibers cannot be identified visually and the information provided by the manufacturer on the label must be trusted.

Material of warp yarn

Another issue addressed in the machine carpet standard; The material is yarn. The material of this yarn is cotton or polyester cotton. The warp yarn is placed along the length of the carpet. In first-class carpets, the yarn is made of 100% cotton. But it is also possible to use polyester cotton yarn. In carpets made of bcf yarn, it is possible to use bcf fibers to reduce the price of warp yarn.

Fabric yarn material:

To fasten the sleeping yarn to the carpet, the roots must be fastened to the carpet. For this purpose, weft yarn is used. The weft thread enters the carpet in a horizontal direction. This yarn is fastened to the carpet by the comb of machine-made carpet. The standard machine-made carpet introduces jute or cotton yarn.

What is Jute?

Jute yarn is a natural fiber found in India and Bangladesh. Jute yarn has 4 qualities that the higher the quality of jute yarn, the finer the carpet material will be.

Types of standard machine carpet density

Shoulder density in meters

Another important piece of information covered in the carpet standard is the shoulder density in meters. Today, the shoulder range of machine-made carpets is usually between 700 and 1500 combs. The higher the number of machine-made carpets, the finer and fuller the carpet will be.

Fabric density in meters

When we talk about density in machine carpet, we mean the same density of fabric per meter. The standard density of machine carpet is from 600 wefts per square meter to 3600 in carpet. The higher the density of the fabric, the higher the compactness of the carpet, which in turn will increase the cost.

Node density in meters

Although it is not maneuverable like the transverse and longitudinal density of the carpet at the time of sale, the standard machine-made carpet has required manufacturers to reduce the density of the knot. The more knots per square meter, the better the quality and durability of the carpet will be over time.

Standard dimensions of machine carpet

The standard for machine-made carpets is invoiced by mentioning specific dimensions. But in order to distinguish the standard, the tolerance limit is defined. The tolerance limit refers to the tolerance of the dimensions that the carpet can withstand the force. This tolerance limit according to standard number 10753 is as follows.

The tolerance limit is 2.5% and 1.5% in length and 1.5% in width. But carpet companies adhere to a dimensional standard.

The final word

As mentioned, the standard information on the car carpet that is placed on the label, this information is not such that it can be detected by either the eye or household appliances, but requires laboratory equipment. Unfortunately, in recent years, it has been observed that counterfeit labels are printed and stamped on machine-made carpets. In order not to be caught by such fraudsters, it is better to buy your carpet from factories.