What is the standard of machine carpet? What are the dimensions of a standard rug?

Rugs can add texture, color, and design to any space. Compared to carpets, rugs are a portable and easy-to-maintain option. But what is the machine-made carpet standard? What are the standard dimensions of a carpet? And is it possible to weave and choose a carpet with custom dimensions? To know the answers to these questions, stay with Dariush Carpet Magazine until the end of this article.

Machine-made Carpet Standard

In the Iranian Standard Law, all companies and manufacturers are required to produce all their products in accordance with Iranian standards. In the meantime, machine-made carpets, like other consumer goods, are required to comply with these standards.

Complying with the standards and restrictions that exist regarding carpets is very important for the buyer in the first stage because complying with them guarantees the health of family members, but in some other products, if these standards are not met, it will have a negative impact on the health of family members.

Importance of the Standard Mark

One of the reasons why it is necessary for a carpet to have the standard machine-made carpet mark is to be able to distinguish a poor-quality machine-made carpet from a high-quality machine-made carpet. On the other hand, the standard dimensions of a machine-made carpet cause carpets of a specific size to exist in the market, which can help the buyer when choosing a machine-made carpet.

All machine-made carpet manufacturers, in addition to using high-quality fibers, must produce their carpets with standard dimensions, because observing this factor is very important in entering global markets.

Currently, one-third of machine-made carpets produced in Iran are exported abroad. Note that the global market is a place for competing with quality, and if the manufacturer does not observe these standards, it will have no achievement other than failure in global markets.

Since the Iranian standard mark is acceptable and trusted by many countries, exporters are required to comply with the standards of this organization. Of course, this mark also provides domestic buyers with the opportunity to purchase carpets with peace of mind.

Machine-made carpet standard, machine-made carpet quality

A standard is not one of the factors that can be measured with the eye or with the equipment you have at home, but rather requires precise technical tools and equipment.

In every carpet manufacturing factory, there is a laboratory unit to examine the quality of the products produced, for this reason, samples are sent to the standard department at different periods, and that organization will issue the relevant seal to the company after careful examination and compliance with the standard items.

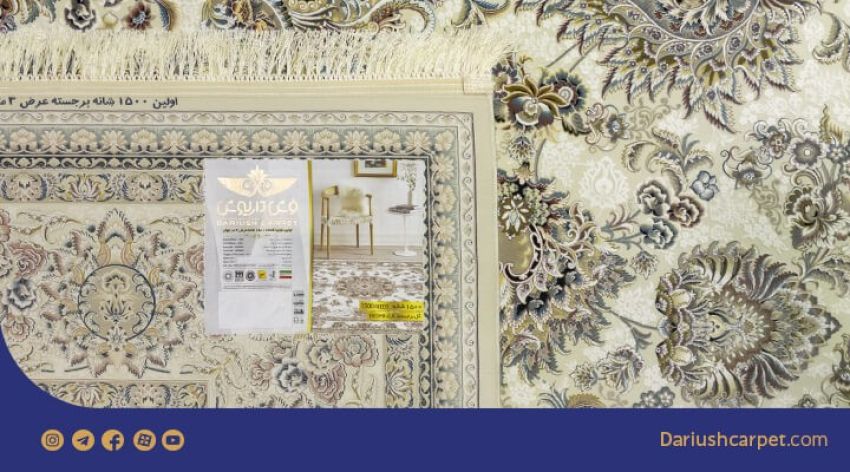

Machine-made carpet standard on the carpet label

One of the machine-made carpet standard items is the standard label that is placed on the back of the carpet. This standard code with the number 1360 is related to information that should be communicated to the carpet buyer. In fact, the buyer can obtain the information he needs by looking at it.

This information includes technical information that can be effective in the final quality of the carpet. If you intend to buy a machine-made carpet, you need to check and control this information.

Machine-made carpet fiber standard

Carpet pile yarn: The first item included in the carpet label is the pile yarn. The pile yarn is used as the carpet ground yarn. According to the standards of this organization, the pile yarn is selected from acrylic, polyester and polypropylene fibers, which means that the machine-made carpet must be produced with one of these three yarns.

Pile height: The pile height is determined according to the yarn type and density of the carpet, but the height range of this yarn will vary from 3 to 25 mm. Machine-made carpets are divided into two groups according to the pile yarn criterion: homogeneous carpets and non-homogeneous carpets.

Homogeneous carpet: It refers to a carpet in which the pile yarn is the same in terms of shape, material, density and height on the surface of the carpet.

Non-homogeneous carpet: A carpet in which the pile yarn is not the same in terms of shape, material, density and height on the surface of the carpet, and even in some areas of the pile yarn carpet there is no pile yarn.

Note that the higher the number of reeds in a carpet, the lower the pile yarn height becomes. As a result, the effect of the carpet becomes more and better visible. Higher reed and density give the final product a more beautiful and elegant appearance, which is why these carpets are called hand-woven carpets.

Carpet and pile quality grade

Machine-made carpets are divided into five quality grades after production. The standard states that if it is to be considered a first-class carpet, the carpet must

- be free from any defects.

- The pile in such carpets is made of heat-set acrylic fibers.

Note that carpet fibers cannot be visually identified and it is necessary for the manufacturer to include this information on the label so that the buyer can purchase the desired carpet with confidence. For this reason, it is necessary to choose a reputable brand with a long production history for your carpet.

Examining the characteristics of machine-made carpet pile

Standard machine-made carpet pile is selected from acrylic, polyester, and polypropylene fibers. These fibers are available in the market with different quality grades. However, a point that is rarely addressed is that if these fibers undergo the heat-set process, they are improved.

In the heat-set process, it is necessary for the fibers to pass through a hot water steam tunnel before weaving, which improves their strength and quality. These fibers have the lowest amount of pilling and are a good choice for children's bedrooms and people with respiratory problems. These threads are also more resistant to heat, moisture, and abrasion.

Characteristics of a good machine-made carpet

- When you touch the carpet, you should not feel any knots or inconsistencies under your hand.

- The pile thread should pass through your hand in a grainy manner.

- The carpet should be transparent and beautiful in appearance.

- The carpet should not have any unpleasant odor.

- The carpet should not have pilling.

- The type of warp thread

Another item addressed in the carpet standard is the type of warp thread. Cotton or polyester fibers are used for the warp. The warp is placed along the length of the carpet; in first-class carpets, all the warp threads are made of cotton. But for lower-grade carpets, that is, carpets produced with BCF fibers, BCF fibers are used for warp fibers because they want the final price of the carpet to be lower.

Weft yarn type

In order for the pile yarn of the carpet to be strengthened to the roots and the life of the carpet to be increased, it is necessary to use weft yarn for the carpet. The weft yarn is added to the carpet horizontally. This yarn is beaten into the carpet by a machine-made carpet machine, and the standard machine-made carpet is selected from the weft yarn made of jute or cotton.

Types of reeds and density of standard machine-made carpets

Another important information that is addressed in the machine-made carpet standard is the carpet reed. Today, the reed of a machine-made carpet is usually selected between 700 and 1500 reeds. The carpet reed means the number of knots woven in one meter of the width of the carpet, and the higher the number of machine-made carpet reeds, the finer the final product will be.

A 700 reed carpet does not have a high density, and for this reason its pile yarn height is higher. On the other hand, 1500 reed carpets have the highest cross-sectional density, which is why the pile height in this flooring is at its lowest. Remember that the thickness of a machine-made carpet is affected by reed and density.

Weft density per meter

When talking about the density of a machine-made carpet, it means how many knots are woven per meter of the carpet. The more weft knots, the higher the density, and as a result, the higher the final price of the product.

Standard Machine-Woven Carpet Dimensions

Machine-woven carpets can be produced in standard or custom sizes, but machine-woven carpets are produced in the following standard sizes:

- 12 meters with dimensions of 4*3

- 9 meters with dimensions of 3.5*2.5

- 6 meters with dimensions of 3*2

- 4 meters with dimensions of 2.25*1.5

- 4 meters with dimensions of 4*1

- 3 meters with dimensions of 3*1

- 2 meters with dimensions of 2*1

Carpets can also be produced in rectangular, square, circular and oval shapes. Each of these shapes is suitable for a specific space in the home, so it is necessary to pay full attention to the features of your decoration before purchasing.

Home layout using standard carpet dimensions

In order to have a better and more accurate layout, it is necessary to know the standard dimensions and purchase the desired carpet according to the taste and style of home decoration. Shapes such as circles and ovals are not suitable for every space and are only used in specific spaces. For example, a circular carpet is used as a mat, bedroom carpet or balcony.

For example, using round carpets as the main carpet is not a good option for small spaces. Round carpets are used as mats, balcony carpets and bedroom carpets in small spaces. Keep a minimum distance of 20 cm to one meter according to the dimensions of your living room. When choosing a carpet, keep in mind whether you plan to place your carpet under the furniture or not, and this can help you greatly in choosing the dimensions and shape of the carpet.

Final Words

As mentioned, the standard information of machine-made carpets is included on the label on the back of the carpet. This information cannot be detected with the eye or household tools, but requires laboratory equipment. If you have any questions about choosing and purchasing the right machine-made carpet, you can call 09139992039 and order your carpet.